Strength in every weld, safety in every flow.

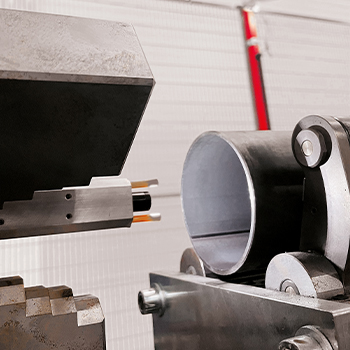

Pro Piping Products specialises in the production of high quality prefabricated sprinkler pipes. We implement strict control measures to ensure each pipe meets the highest industry standards. Our new installations for welding, roller grooving, and painting are completely automated, guaranteeing high and consistent quality of welded products. Depend on Pro Piping Products for efficient, trustworthy, and durable piping solutions that seamlessly fit into your sprinkler system.

.

Quality testing

Automatic pipe seam

detection & positioning

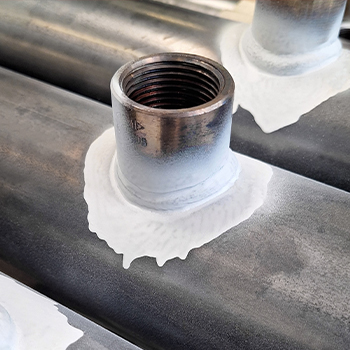

Liquid

penetrant testing

Thermal

optics QA

.

Why choose for our prefab sprinkler pipes?

Certifications and standards

We have established extensive quality control systems both upstream and downstream.

This way we guarantee ultimate safety and 100% leak proof sprinkler pipes.

- FM standard approval (coming soon)

- EN 10217-1

- ISU certificate

- ISO 9001

- ISO 14001

Characteristics

- Standard 10217-1 steel grade P235TR1.

- Rolled groove dimensions according to AWWA C606.

- Pipe length tolerances = 0/+10mm.

- Working pressure:

pressure nominal = 20,7 bar / 300 psi.

For a good understanding of our products, we refer to our brochure. In it you will find more technical information.

Finishes

With different finishes, we are able to perfectly fit your preferences:

- Standard colour: epoxy RAL 3000.

- Other colours: on request.

- Galvanised: on request.

The colours are applied using an electrostatic powder painting process.

.

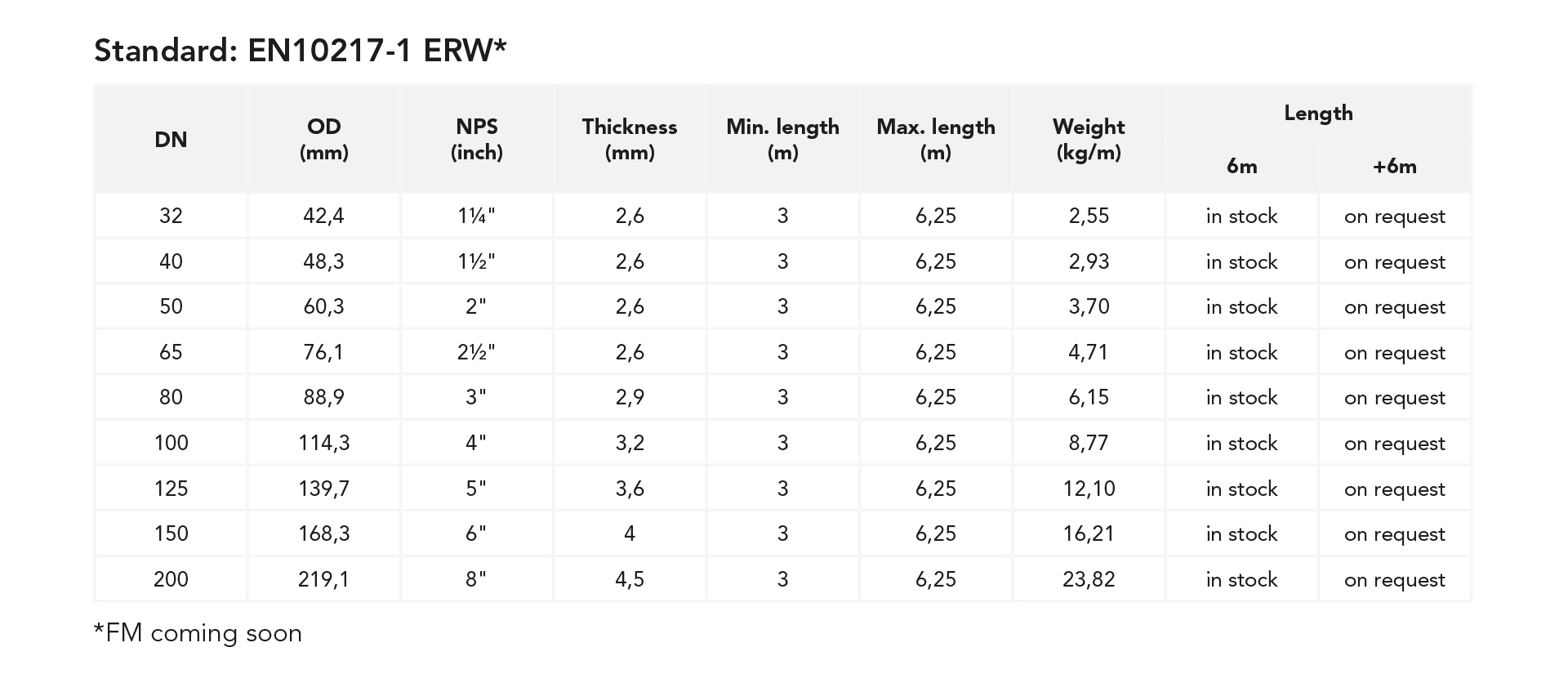

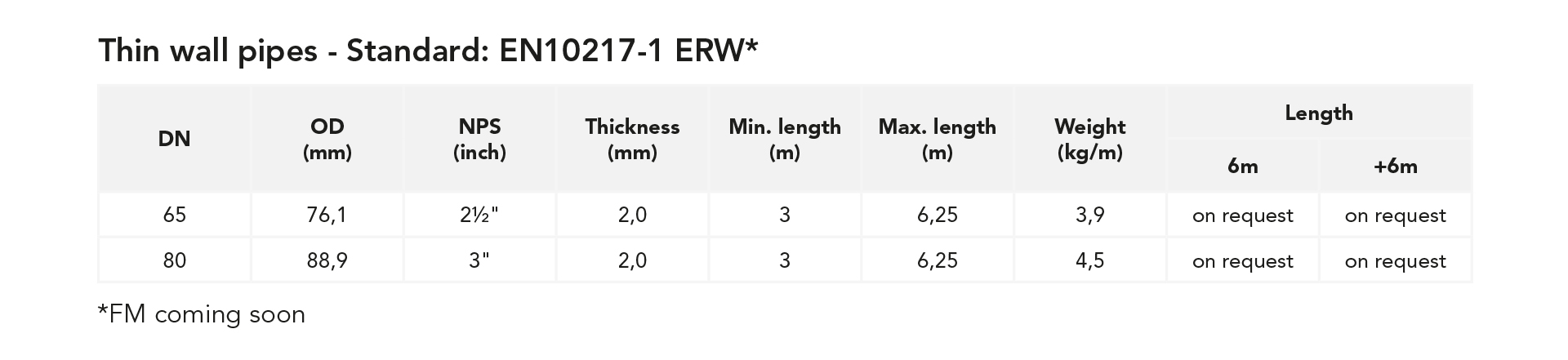

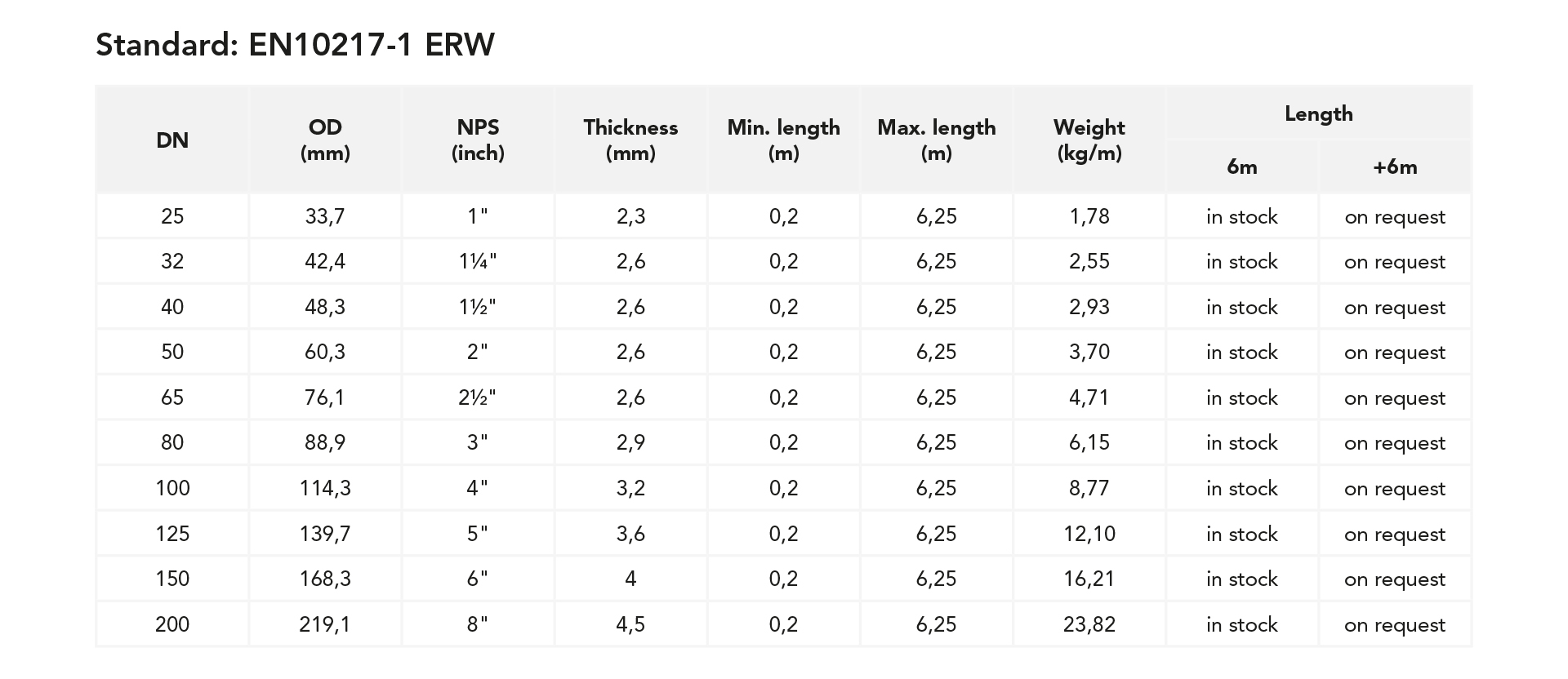

Dimensions - values: prefabricated sprinkler pipes

.

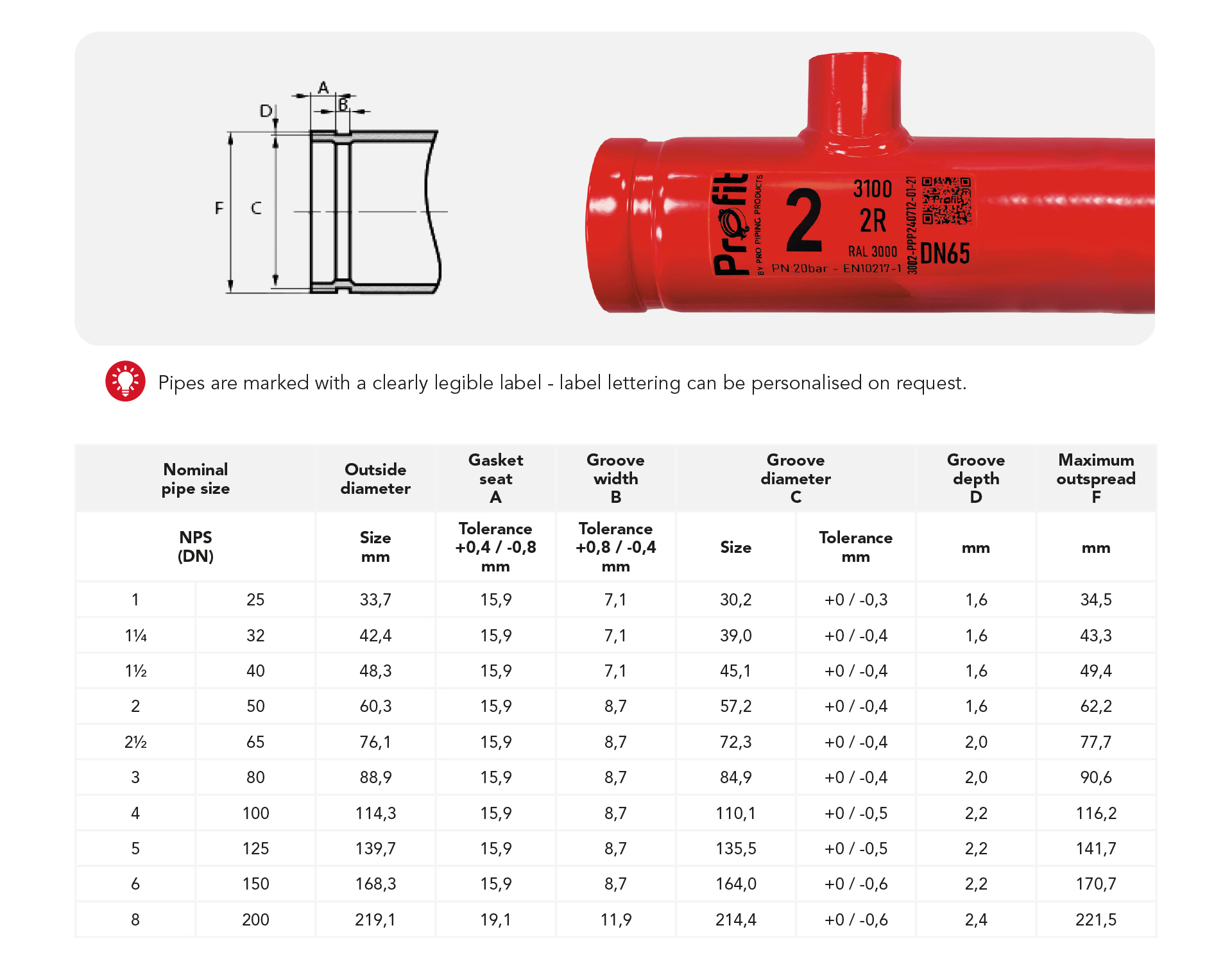

Dimensions - values: plain end pipes and grooved sprinkler pipes (without outlets)

Rolled groove dimensions according to AWWA C606

.

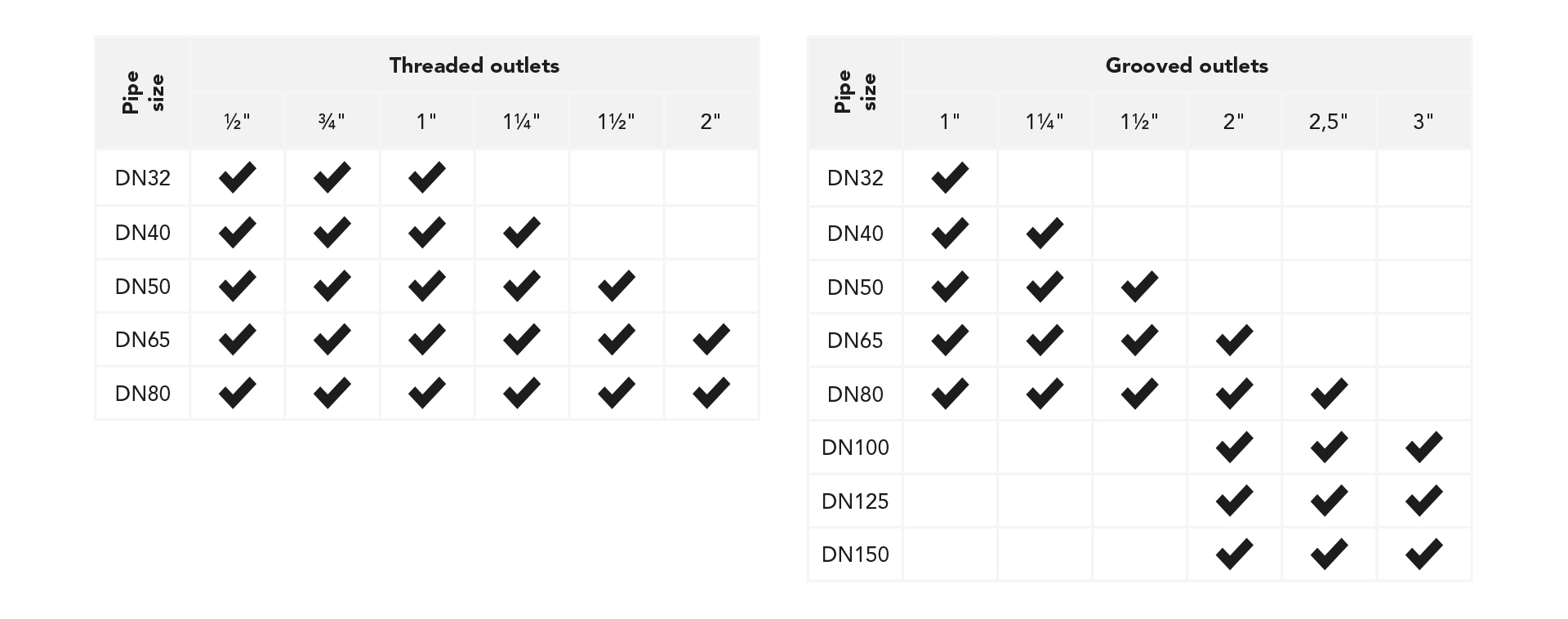

Outlet combinations

.

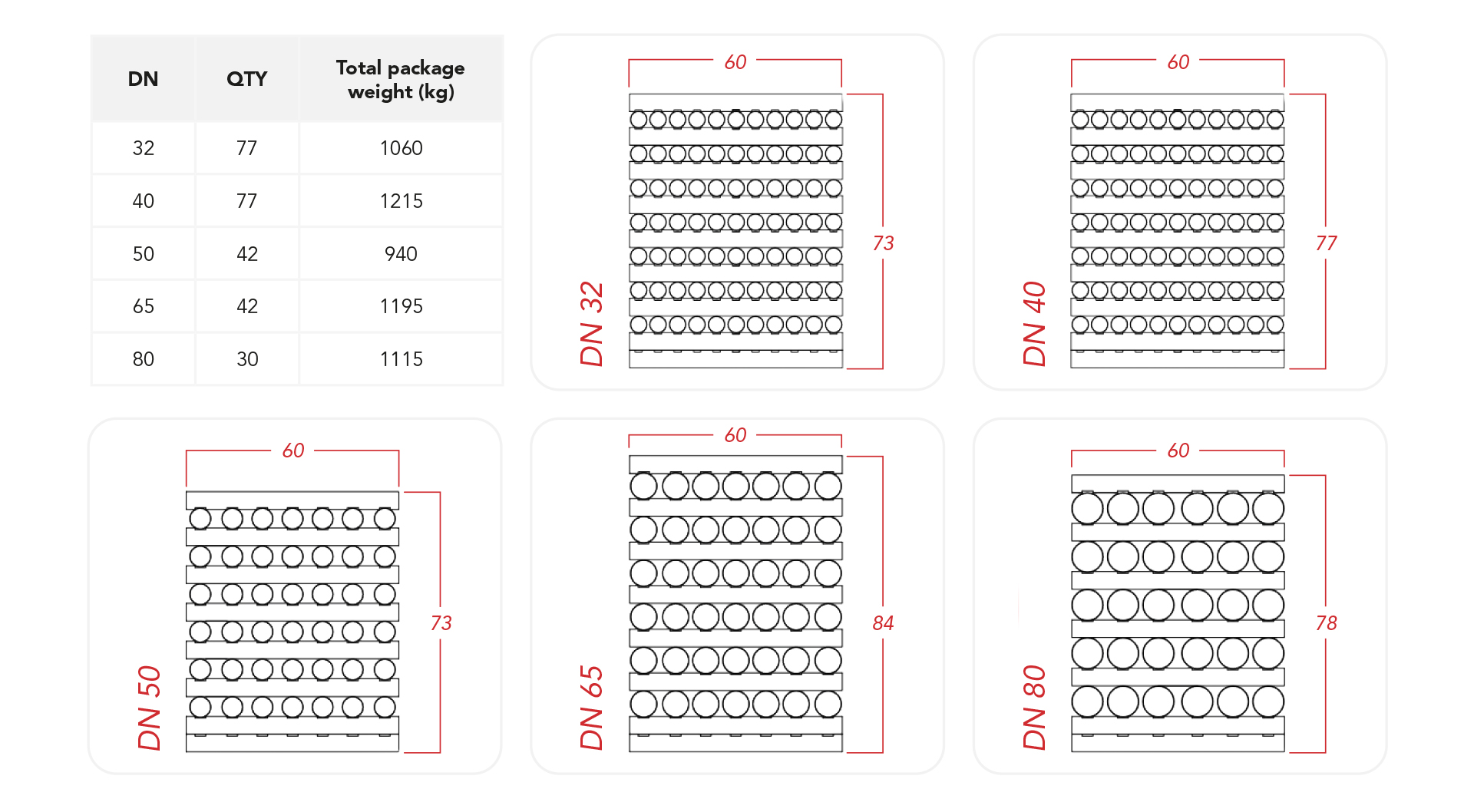

Standard package 6m pipes

.

More info